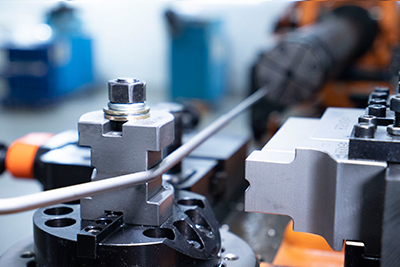

Carbon steel: ASTM/ASME A234 WPB, WPC

Alloy: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP911, 15Mo3 15CrMoV, 35CrMoV

Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N

ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti

ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

Low temperature steel: ASTM/ASME A402 WPL3-WPL 6

High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70

Cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon, PVC, PPR, RFPP(reinforced polypropylene) and so on.

Aluminum alloy 3003,6061, copper, copper, brass