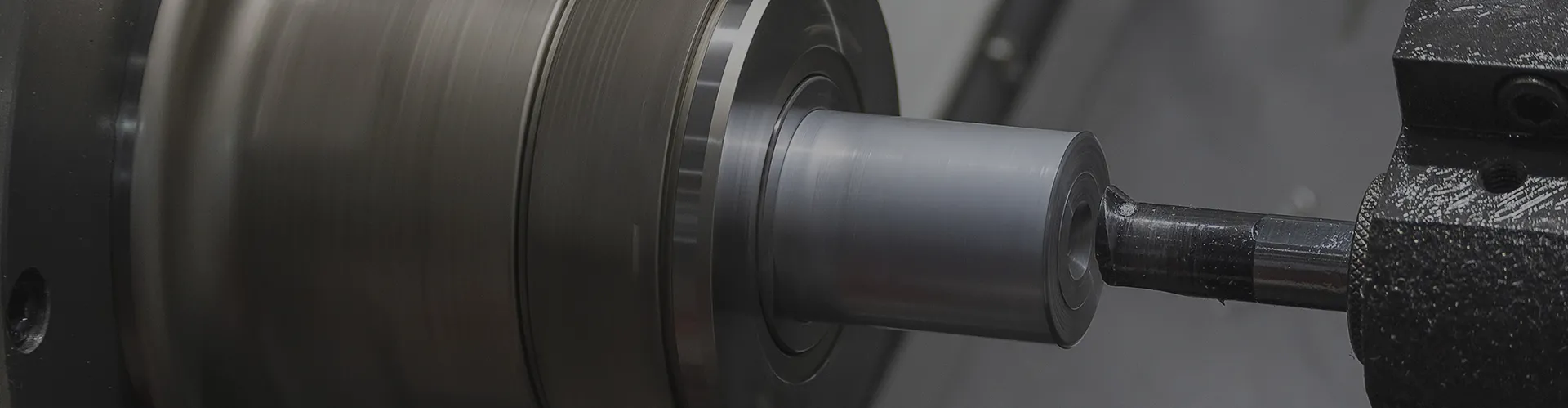

Boring is designed to enlarge the aperture, improve the accuracy and reduce the surface roughness, compared with drilling and reaming, the size of the boring is not limited by the size of the tool, and the boring has a strong error correction ability, which can correct the deviation error of the original hole axis by multiple cutting, and can make the boring hole and the positioning surface maintain a high position accuracy. Therefore, the processing range of boring is wide, and various holes of different sizes and different precision levels can be processed.

Boring is almost the only machining for holes with large aperture and high position accuracy requirements.