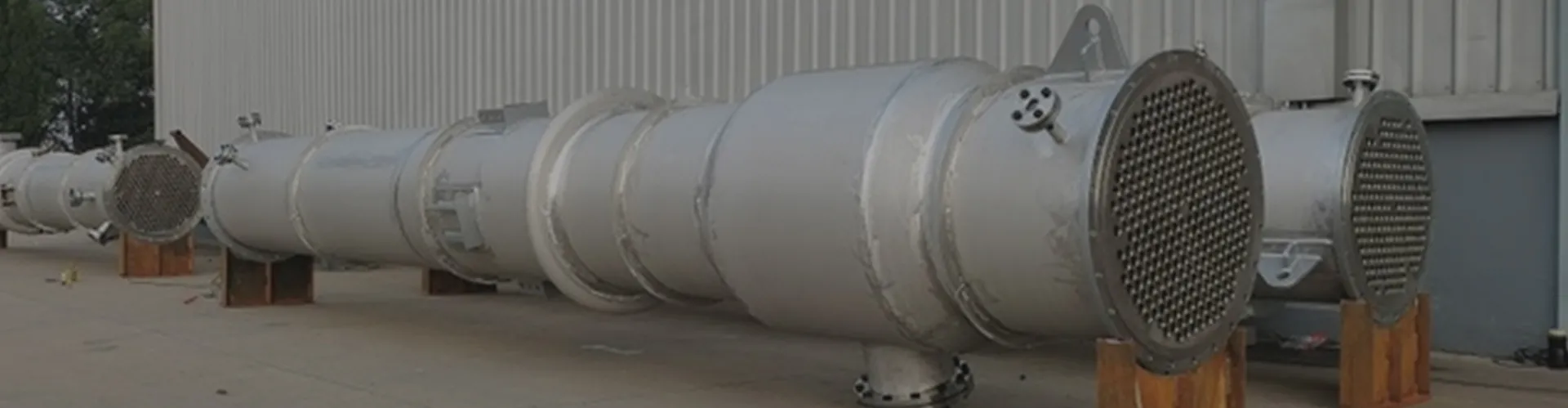

The refrigerant vapor condenses on the outer surface of the pipe, and the cooling water flows in the pipe under the action of the pump. The refrigerant vapor enters the person from the upper intake pipe, condenses into liquid, and flows into the reservoir through the outlet pipe at the lower part of the cylinder. Both ends of the barrel of the condenser are sealed with an end cover, and a water separation partition is used in the end cover to realize the multi-pipe flow of the cooling water. The number of tube bundles of the condenser is even, so that the inlet and outlet of the cooling water can be arranged on the same end cover, and the lower inlet and the upper outlet.