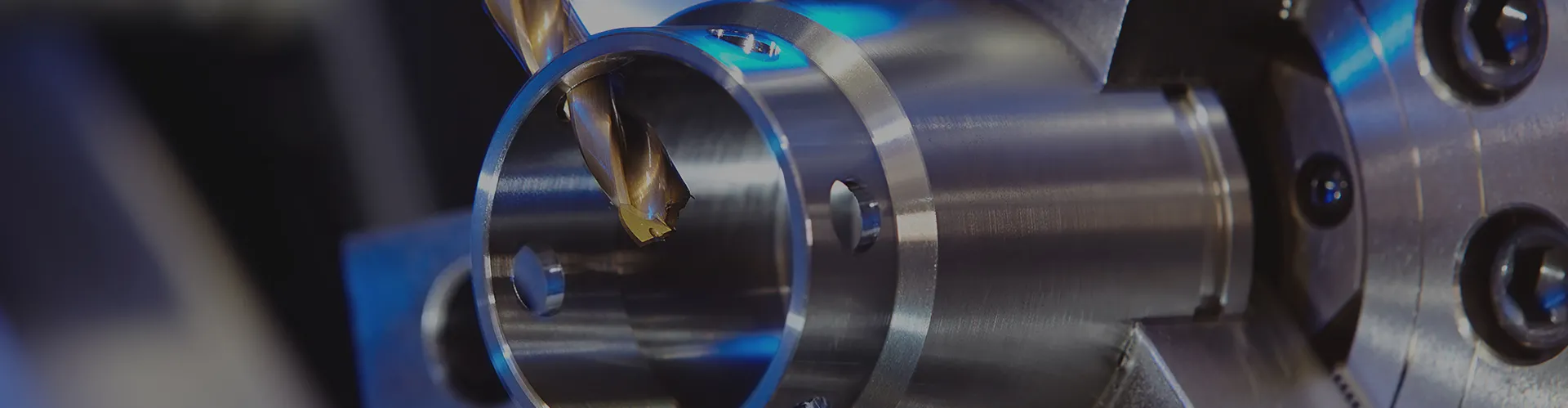

Processing & Standard

Common drilling processing is first based on the characteristics of the material, drilling depth, hole size, material hardness has been modulated, normalizing and other conditions to select the corresponding processing equipment and the correct tool deployment. For example, ordinary Q235, GR40, GR70, 16Mn, carbon steel, the material is soft, and the general twist drill can be processed, compared to F60, S316L, S2205 and other special materials need to use special tools (TDMX, TC4...)

However, it is always necessary to choose comprehensively according to the processing requirements, such as the hole diameter tolerance ±0.01mm, the inner wall finish of the hole Ra0.8~1.6, and the verticality of ⊥ Φ0.05 also need to be assisted by boring, reaming, grinding and other processes

|  |  |  |

TDMX | TC4 | Vari Drill | TRF / TRM |

Extra stable pocket seat in tough conditions, resulting in an increase of productivity and decrease in cost per hole | Versatile Indexable drilling platform covering a wide range of materials and applications design enables high feed rates | Universal Solid Carbide Drilling portfolio, suitable for Steel, Stainless Steel and Super Alloys | New brazing even technology enabling higher feed higher feed |