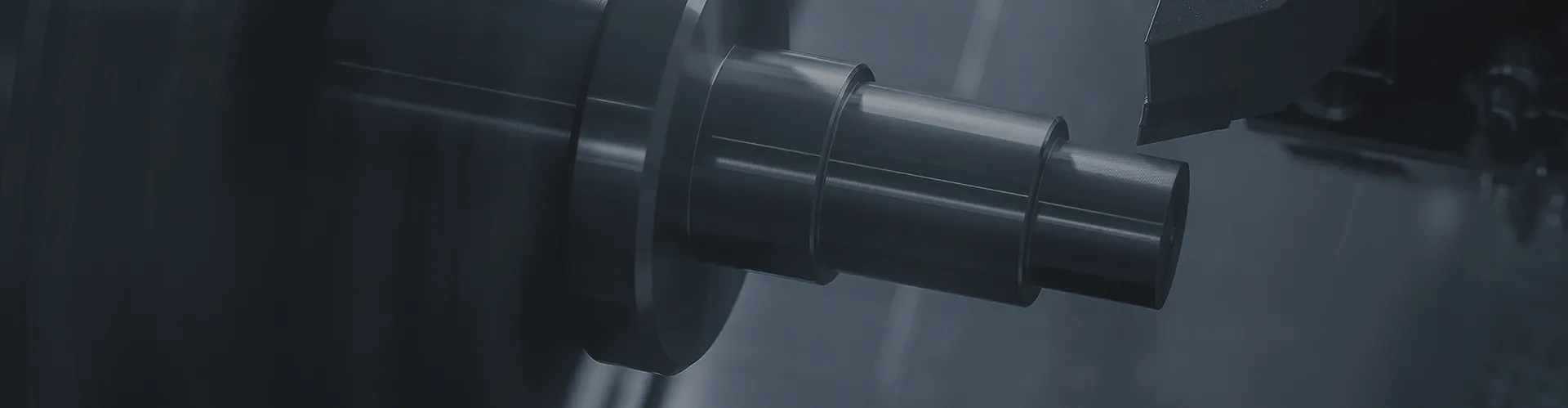

Precision Lathe Turning For Metal Parts: High Precision Manufacturing of Metal Components

In modern manufacturing, precision lathe turning is one of the key processes for producing high-quality metal parts. Whether in aerospace, automobile manufacturing, medical devices, electronic equipment, or other fields, the requirements for the precision and quality of metal parts are increasingly stringent. SENLYON precision lathe turning service focuses on providing customers with high-precision, highly reliable metal component manufacturing solutions.

Service Advantages

High Precision Machining Capability

We utilize advanced CNC lathes capable of achieving extremely high machining accuracy, with tolerances controlled within ±0.0005 inches (0.0127 mm) or better. Whether it's complex geometries or precise dimensional requirements, our equipment and technical team ensure accurate part fabrication.

Diverse Material Selection

We support the machining of various metal materials, including but not limited to stainless steel, aluminum alloys, copper, titanium alloys, etc. These materials are widely used across different industries to meet diverse customer needs.

Rapid Delivery and Small Batch Customization

Understanding the importance of delivery times and customization, our machining center can quickly respond. Whether it's small batch customization or mass production, we provide rapid delivery services while ensuring quality. We accept single orders for research, sample testing, and can swiftly move into production and deliver small batch orders.

One-stop Solution

From design to finished product, we offer a one-stop machining service. Customers only need to provide design drawings or 3D models, and we will provide an instant quote within 24 hours. Utilizing advanced machining technologies, we rapidly transform designs into high-quality finished products.

Application Scenarios

Aerospace

In the aerospace sector, we manufacture high-precision turbine blades, structural components, meeting stringent tolerances and material requirements.

Automobile Manufacturing

For automobile manufacturing, we provide high-precision engine blocks, suspension components, ensuring reliable operation under high strength and precision demands.

Medical Devices

Our precisely manufactured surgical tools and implants meet the strict precision and safety standards of the medical industry.

Industrial Machinery

For industrial machinery, we supply high-precision metal casings, gears, ensuring stable operation under complex conditions.

Technology and Equipment

CNC Lathes

Our CNC lathes feature 2-axis, 3-axis, and multi-axis machining capabilities, capable of performing external and internal cylindrical turning, face turning, taper turning, boring, drilling, threading, and more.

Advanced Inspection Equipment

Equipped with advanced inspection equipment, we ensure that every part meets the required precision and quality as per the design specifications.

Contact Us

We are dedicated to providing customers with high-quality precision lathe turning services. If you have any needs or questions, please feel free to contact us. We will provide professional technical support and customized solutions. Choose us to make your metal part machining more efficient, precise, and reliable!