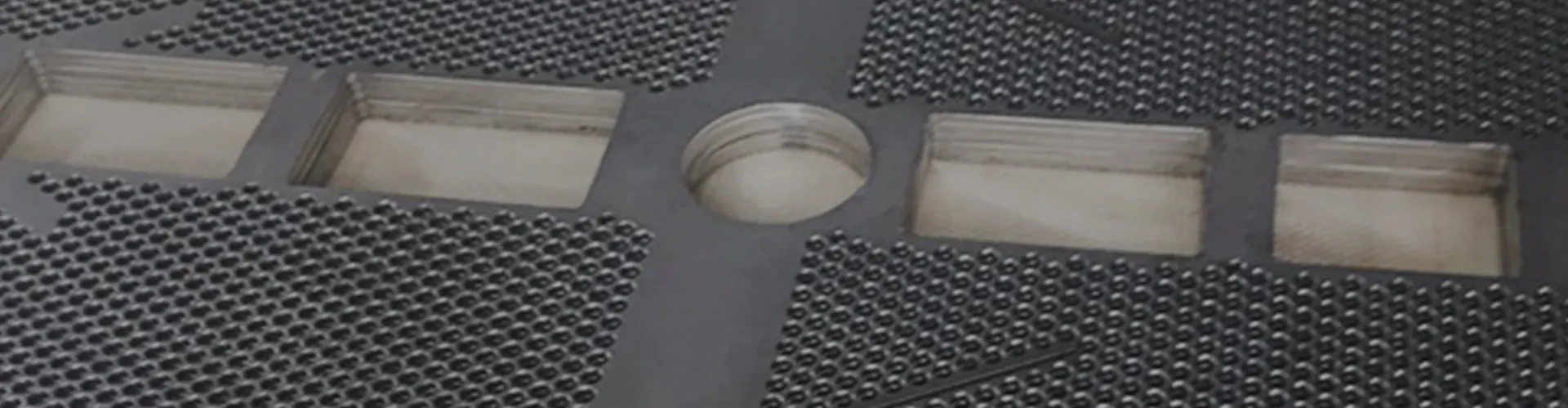

The length of the channel of the shell medium is extended, the flow rate between tubes is increased, the degree of turbulence is increased, and the heat transfer effect of the heat exchanger is improved.

Senlyon is a leading supplier and manufacturer of baffle plates, specializing in high-quality, durable, and cost-effective solutions for industrial and commercial applications. With years of experience and a commitment to excellence, we have become a trusted name in the industry, delivering customized products tailored to meet specific requirements.

Our Products

Standard Baffle Plates: Designed for efficient flow control and durability, ideal for general industrial use.

Custom Baffle Plates: Tailored to fit unique designs and dimensions for specialized applications.

High-Temperature Baffle Plates: Engineered to withstand extreme conditions in heat-intensive environments.

Corrosion-Resistant Baffle Plates: Perfect for use in chemical and marine industries.

Customization Options

Our baffle plates can be customized to meet your specific needs. We offer:

Various materials including stainless steel, carbon steel, and alloys

Custom dimensions and thickness

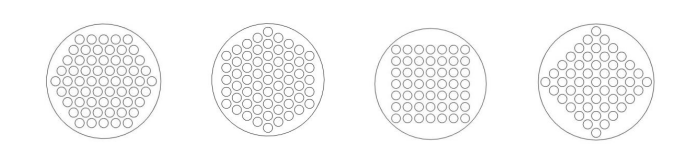

Perforation patterns and flow specifications

Surface treatments like anti-corrosion coatings and finishes

Design assistance to ensure optimal performance

Contact us to discuss your project requirements and get a custom quote!

Applications

Our baffle plates are designed for a wide range of industries and applications, including:

Heat Exchangers: Enhancing heat transfer efficiency and flow distribution.

Boilers: Improving thermal performance and ensuring operational safety.

Water Treatment Systems: Facilitating flow control in filtration processes.

Oil & Gas: Ensuring durability in high-pressure environments.

Chemical Processing: Resistant to corrosive substances for reliable performance.

Ready to find the perfect baffle plate solution for your needs? Reach out to us today!